Offer

Naftoremont-Naftobudowa, a Polimex Mostostal Group company, possesses highly specialized and wide-ranging competences in the scope of investment, modernization and renovation for the petrochemical-refining, chemical and oil and gas industry and storage.

The purpose of its activities is to provide specialized services for the development of industry in Poland and Europe by ensuring a high and stable level of quality in the work performed.

The range of experience and services offered by Naftoremont Naftobudowa includes design, purchase and supply of materials, prefabrication, assembly of equipment and installations, commissioning and start-up, service and maintenance, repairs and modernization, as well as expansion of industrial installations.

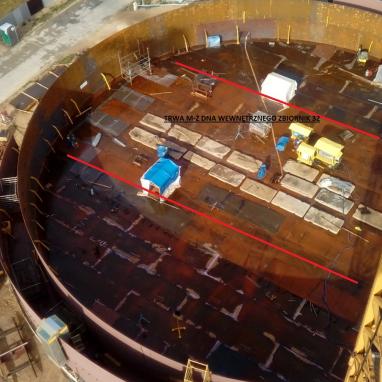

The Company's main business is investment projects carried out under the General Contractor or EPC - “turnkey” formula in the area of construction of storage tanks, industrial installations, terminals and transshipment ports, fuel pipelines.

A crucial element of Naftoremont-Naftobudowa's activities within the refining and petrochemical industry are repair services during installation shutdowns, the so-called turn-around requiring a huge commitment of personnel resources as well as human potential within a short deadline - the Company has proven that it can cope with such huge and demanding projects at home and abroad.

Naftoremont-Naftobudowa possesses competences and employs specialized staff in the gas sector. The business in question involves the construction as a General Contractor of gas infrastructure, i.e. gas transmission pipelines, gas stations, gas compressor stations.

Naftoremont-Naftobudowa also implements facilities related to water and wastewater management. As a General Contractor, we build sewage treatment plants with sludge management, water treatment stations, water and sewage pumping stations and water and sewage networks.

Naftoremont-Naftobudowa manufactures furnaces and process heaters while offering on-site installation and commissioning.

The company has a diverse and sizable set of machines for welding with the most popular welding methods MIG/MAG, TIG, MMA, SAW at its disposal.

It offers rental of complete welding sets along with experienced operators with valid welding licenses.

Naftoremont-Naftobudowa has specialized equipment used in domestic and foreign projects at its disposal.

Hot Tapping - it is a method of making connections to existing active pipelines or pressure vessels without interrupting or draining that section of pipe or vessel. This means that the pipeline or tank can continue to function while the connection is being made.

Application: inert medium: water, steam, air, nitrogen; hazardous medium: oil, sodium lye, hydrogen fluoride, acids, bases, salts.

Mobile lathes

FF120 - manual machine tool for reconditioning small flange connections. Its compact design and very low weight allow for its use in restricted areas, directly on the installation.

MM1500 - a mobile machine tool designed for precise turning of various types of flange connections.

The RET100BCNC boring machine - for machining large-sized workpieces, it allows for machining steel parts with high dimensional precision, including through-hole and blind hole drilling, reaming, turning and boring, threading and milling.

Reconditioning of industrial fittings

Since 2009, Naftoremont-Naftobudowa has been providing remanufacturing services for industrial fittings. We have a stationary workshop in Płock and a mobile workshop, allowing operational activities during repair shutdowns at the client's site where the fittings are installed.

The workshop is equipped with modern machinery and equipment from EFCO.

We perform:

- remanufacturing of shut-off fittings (wedge gate valves, globe valves, check valves, control valves, butterfly valves in flanged and welded designs in the range of diameters between DN15 and DN800 and pressures up to 20MPa).

- remanufacturing of safety fittings (safety valves with flanged and welded connections in the range of diameters between DN15 and DN400 and pressures up to 25MPa)

- we certify pressure tests and settings with a computer printout.

We perform valve repairs based on the provisions of PN-92/M-74001 (Industrial valves. General requirements and tests) and refinery standards: API 520, API 527, API 576, API 574 and API 598.

For remanufactured safety valves, we issue metrics certified by the Technical Supervision Office.

Non-Destructive Testing Laboratory

The Non-Destructive Testing Laboratory is an organizational unit operating within the structures of Naftoremont-Naftobudowa sp. z o. o. from the very beginning of its establishment.

We specialize in measuring wall thickness (UTT) of facilities using mountaineering techniques (significant reduction in costs and time compared to the use of scaffolding).

In conducting its activities, the Non-Destructive Testing Laboratory is guided by the principle of providing laboratory services at a high level while maintaining the credibility and reliability of the tests conducted.

We take into account the client's individual expectations in particular for works requiring special rope access techniques.

We specialize in working in the following areas:

- Applying measurement grids to tested facilities according to the received measurement and technical documentation.

- Removal and installation of inspection rosettes for taking measurements on industrial apparatus.

- Wall thickness measurements using industrial rope access (according to ASSECURO certificates) on industrial facilities such as pipelines, apparatuses, tanks, columns, heat exchangers, reactors, industrial furnaces, etc.

- Inspections, cleaning and maintenance of fire protection installations.

- Inspection and filming the internal lining of industrial chimneys.

Our employees are qualified to: perform non-destructive testing in various methods, work using mountaineering techniques, heat treatment of welded joints, and we also have employees on staff with qualifications in the field of radiological protection.

We perform the following types of tests:

- visual testing,

- penetration testing,

- magnetic-particle testing

- radiographic testing,

- UT, UT-PA, UT-TOFD, UTT ultrasonic testing,

- hardness tests,

- tightness tests,

- ferrite content tests,

- Staloscopic - PMI

- heat treatment of welded joints - PWHT

We are approved by the Office of Technical Inspection for the NDT tests we perform.

Certifications and attestations held:

- vT2, VT3, PT2, PT3, MT2, MT3, RT2, RT3, UT2, UT3, UT-PA, UT-TOFD, UTT1 certificates,

- ISO 9001 - quality management

- ISO 14001 - environmental management

- ISO 45001 - occupational health and safety management

- EN ISO 3834-2

- EN 1090-1

- PED 2014/68/EU

- AD 2000 Merkblatt HP0

- WHG

- ASME stamp U

- Office of Technical Inspection’s certificate for modernization and repair of tanks, boilers and pipelines

- Office of Technical Inspection’s certificate for manufacturing components of pressure and non-pressure equipment

- Office of Technical Inspection’s certificate for the manufacture of non-pressure and low-pressure tanks for flammable liquids

- Office of Technical Inspection’s certificate for manufacturing non-pressure and low-pressure tanks for poisonous or corrosive materials

- non-destructive testing certificates from the following companies: TUV Rheinland, The Welding Institute, UDT-CERT, Solver

- working with mountaineering techniques from Assecuro,

- use of ActSafe ACX electric winches,

- certificates in the inspection of personal protective equipment

- PWHT training,

- licenses of the Radiation Protection Inspector (IOR-1) granted by the National Atomic Energy Agency

- a certificate of an internal auditor of the PCA laboratory

- an European welding engineer certificate

- SCC/VCA certifications,

- certificates for the installation of flange connections in pressure systems posing particular risks,

- certificates for transporting dangerous goods (ADR-7)

- first aid certificates.

Which brings us to a total of 172 different certificates and attestations used in our daily work.

Rope access works:

We have a team of high-level rope access specialists with ASSECURO training certificates, who at the same time hold non-destructive testing certificates - mainly UTT, VT and PT.

We carry out the works in accordance with applicable standards and internal procedures, as well as in accordance with the client's guidelines.

We have performed research for such clients as: ORLEN S.A., ANWIL Group

We have and work according to the standards of the Integrated Management System:

The basis for the trust placed in the Company by major domestic and foreign clients such as Orlen S.A., Orlen Unipetrol RPA s.r.o., TotalEnergies, bp, Gunvor Energy, Shell, NYNAS AB, NESTE Corporation, BASF, BorsodChem and others is the personnel who have been associated with Polimex Mostostal CG for many years. They gained experience on many construction sites in the country, Western Europe and the Middle East.

Implementation of supplies and services in the petrochemical-refining, chemical and gas industries is an undertaking characterized by the need to comply with extremely stringent requirements for safety and organization of work, adherence to quality standards and compliance with the standards set in the plants where individual tasks are carried out - all these requirements are met by the Naftoremont-Naftobudowa crew - as evidenced by technical approvals, quality certificates and references obtained from customers.