Projects

Projekt realizowany w ramach modernizacji cementowni w Airvault, zlokalizowanej w regionie Nowa Akwitania we Francji. Inwestycja jest częścią strategii zrównoważonego rozwoju Heidelberg Materials, mającej na celu zwiększenie efektywności energetycznej i redukcję emisji dwutlenku węgla w procesie produkcji cementu.

Zakres:

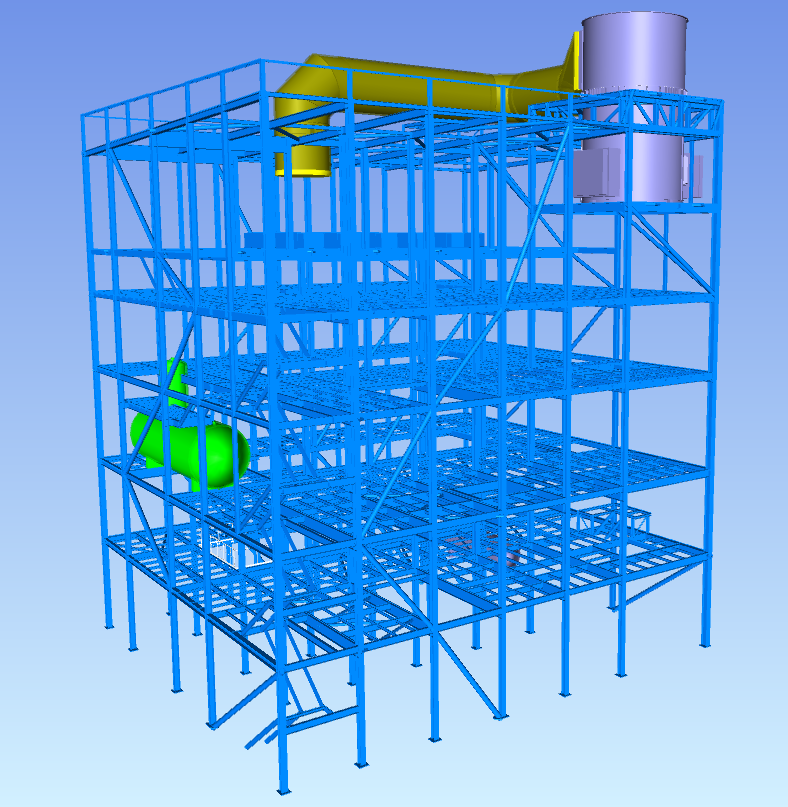

Montaż konstrukcji stalowej budynków infrastruktury nowej linii produkcji klinkieru, w tym:

- Budynek młynów,

- Hale składowania,

- Wieża wymienników,

- Podesty budynków elektrycznych i rozdzielnic.

Tonaż konstrukcji: ok. 2.000 ton.

Lokalizacja: Airvault, Nowa Akwitania, Francja

Termin realizacji: 07.2024 – 05.2025

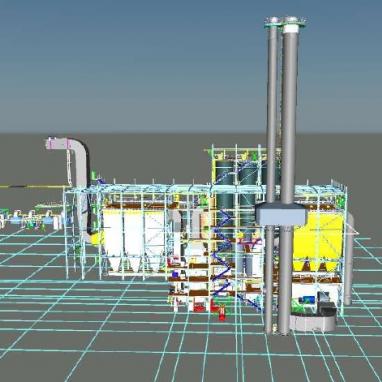

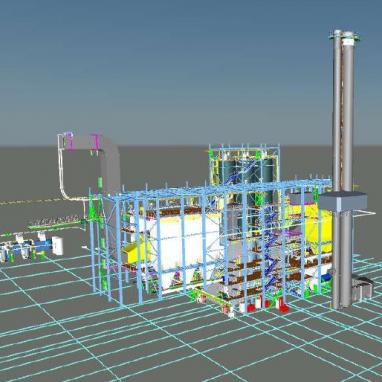

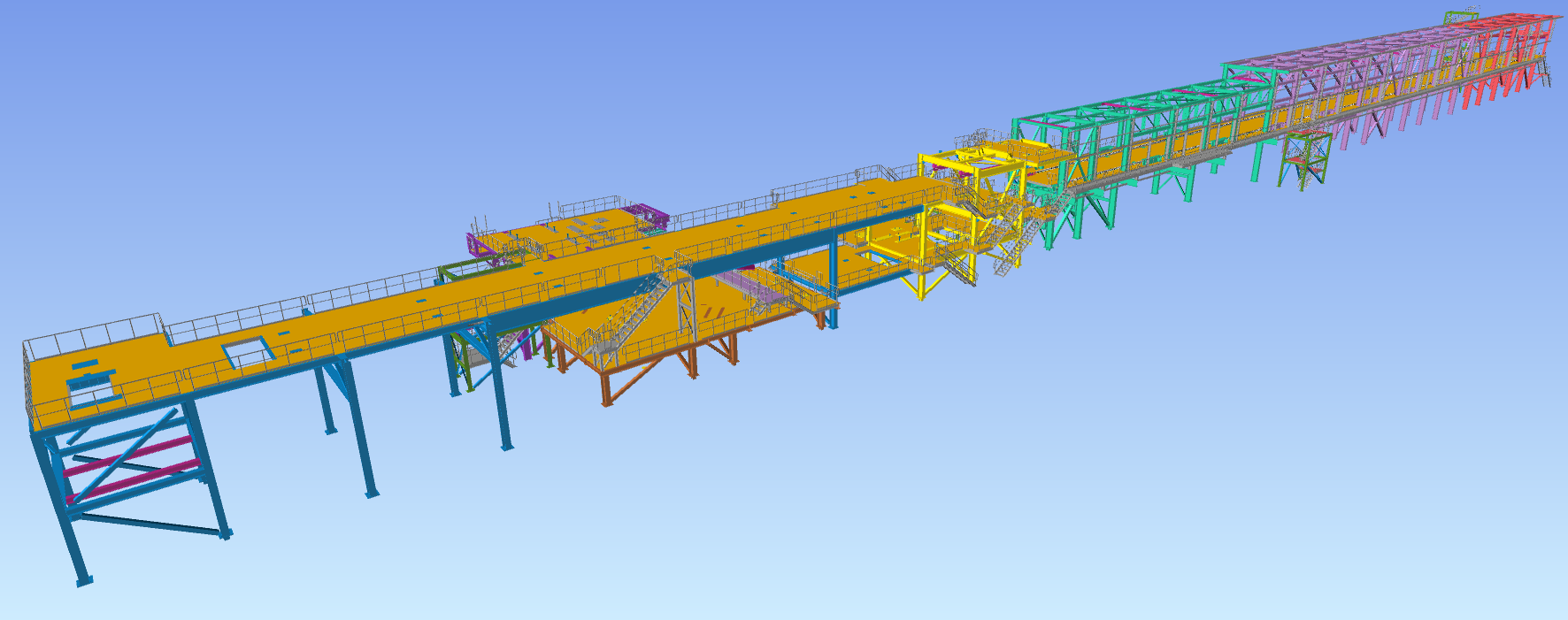

- Scope of works: fabrication, delivery and erection of support steel structure (645 tons) and sheet metal components (ducts, SCR DeNox, silos = 251 tons) and installation of process equipment (ID Fans, Bag House Filters, Mechanical Conveying System, Pneumatic Transport, Tanks, Pumps, Cabinets, Air Production System etc. = 100 tons) for flue gas treatment.

- Final client: EEW Energy from Waste Stapelfeld GmbH

- Tonnage of project: 996 tons

- Location: Stapelfeld, Germany

- Date of realization: 2022/2023

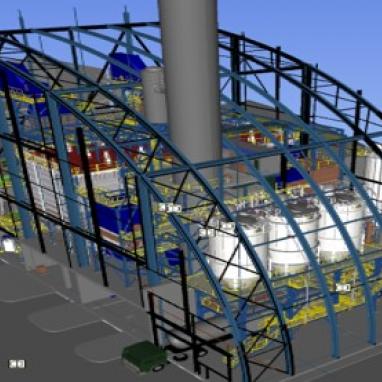

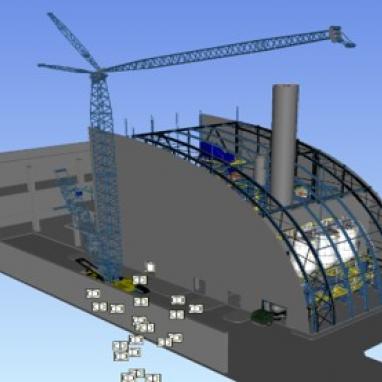

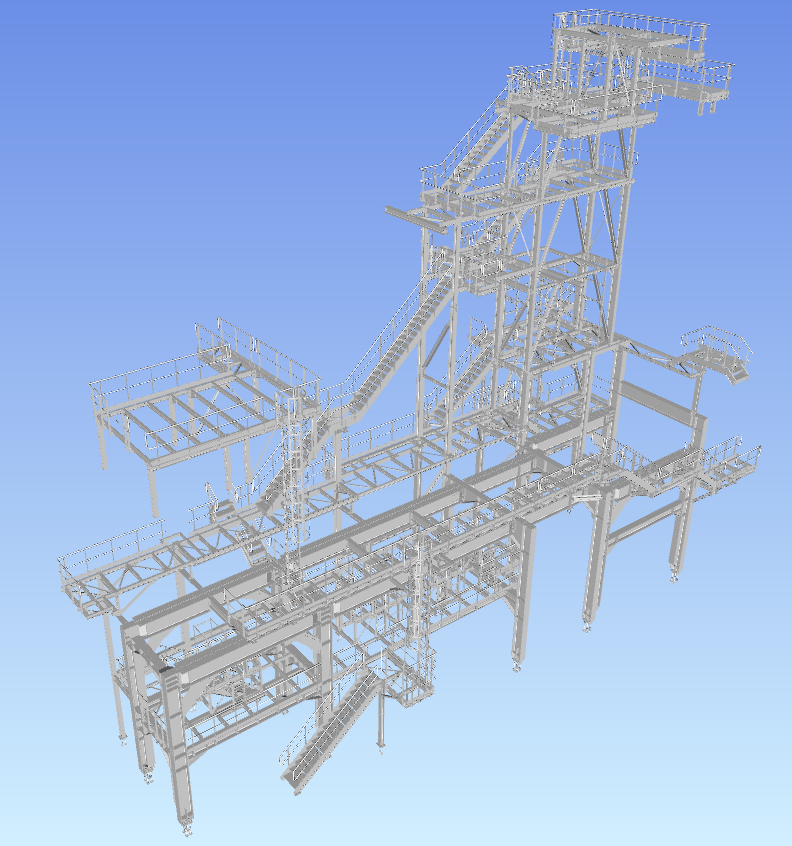

- Scope of works: fabrication, delivery and erection of support steel structure for Flue Gas Treatment installation (309,5 t) in two lines. Installation of process equipment (1.024,12 t) including reactor, Fabric Filter, Catalyst & Eco, ID Fans, ducts, silos.

- Tonnage of project: 1.333 tons

- Location: Bellegarde-sur-Valserine, France

- Date of realization: 2021

Scope of works: engineering, workshop documentation, fabrication, delivery and erection of platforms (50 tons) and steel structure of distribution cabins (34 tons) and also support steel structure for cable trays (50 tons) and delivery of cable trays (about 3.000 meters).

- Tonnage of project: 134 tons including: 50 tons of platforms, 50 tons of support steel structure, 34 tons of steel structure for distribution cabins

- Length of cable trays: about 3.000 meters

- Location: IJmuiden, Netherlands

- Date of realization: 2022 / 2023

- Scope of works: engineering, workshop documentation,fabrication, delivery and erection of a steel structure including strengthening of existing elements, civil works and also delivery and erection of cable ladder elements together with wall and roof cold cladding as a support for new electrical cables to be installed during repair maintenance of the object.

- Tonnage of project: about 180 tons

- Location: iJmuiden, Netherlands

- Date of realization: 2020 / 2021

-

PROJECT KEMSLEY, ENGLAND (UK)

Scope of works: delivery, prefabrication and erection of pipelines and installation of equipment.

Tonnage of project: 69,7 tons of piping, 7 tons of support structure, 14,1 tons of equipment.

Location: Kemsley, England

- PROJECT EARLS GATE IN SCOTLAND (UK)

Assembly of a flue gas treatment unit and the support structure (200 tons) along with the installation of equipment: flue gas ducts, a bag filter, silos, fans and conveyors (254 tons). Project implemented in 2020.

- PROJECT RAMBERVILLERS (FRANCJA)

Assembly of a support structure for the boiler (428 tons) and a flue gas treatment unit (182 tons). Installation of equipment (284 tons): ducts, a bag filter, an SCR reactor, fans, silos or mechanical conveyors. Project implemented in 2020.

- PROJECT AALEN-NEUKOCHEN (DE)

Workshop project, delivery and assembly of steel structures (805 tons) for the boiler room in the paper mill, Aalen-Neukochen, Germany.

- Workshop project, delivery and assembly of steel structures along with a casing for the wall and the roofs of a technological installation (1,100 tons) for the transportation of metallurgical materials to Amsterdam, the Netherlands

- Workshop project, delivery and assembly of steel structures for the boiler room in Annecy, France (130 tons)

Delivery of steel structures for the boiler in Hooton, UK (470 tons)

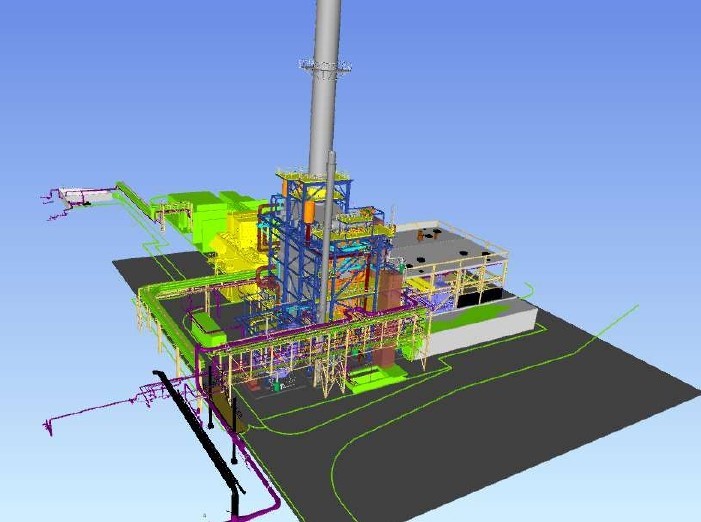

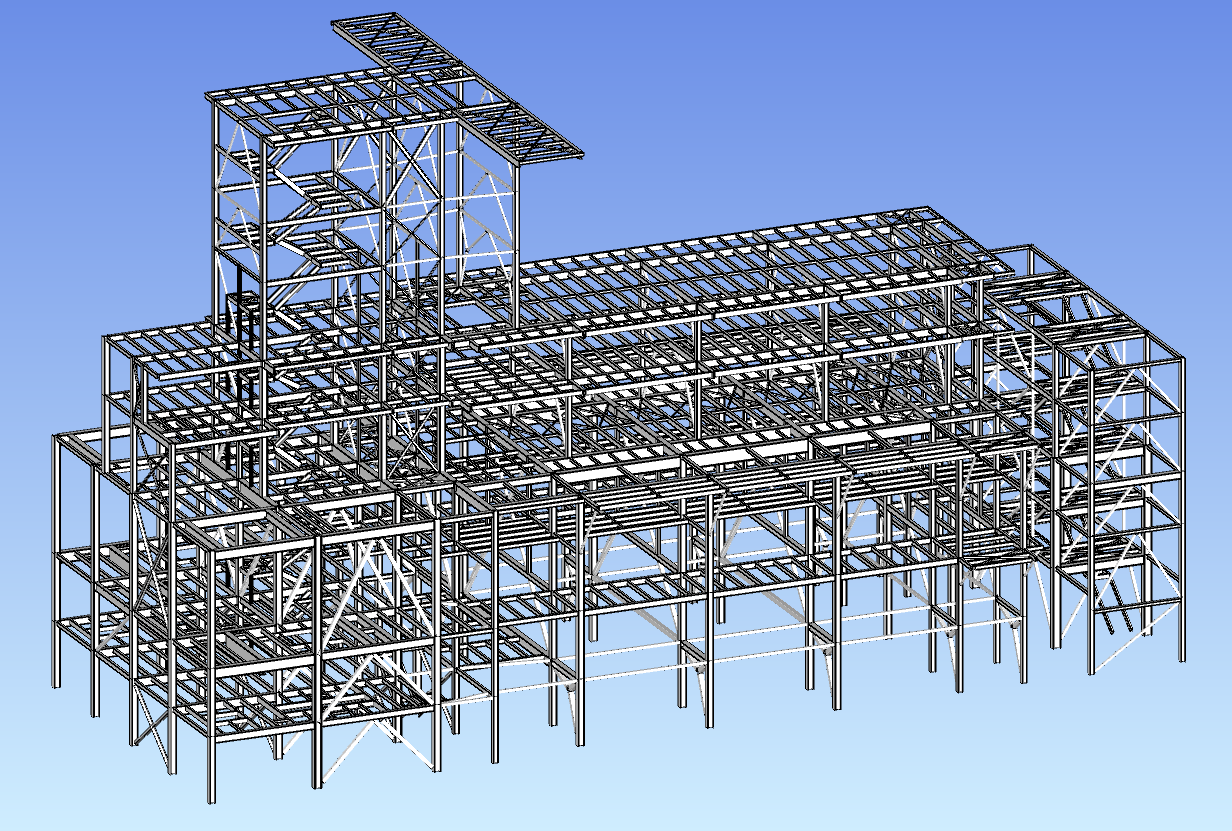

Scope of works: delivery and erection of steel structure for main building, flyovers and auxiliary buildings.

Tonnage of steel structure: 2.700 tons

Installation of two boilers HRSG with piping.

Installation of two gas turbines SGT-800.

Location: Siechnica, Poland

Date of realisation: 07.2021 – 07.2024

Project OLEFINY III - fabrication and installation of pipe-racks with piping as part of the works under investment task no. 22019/9/003 entitled "Intensification of Olefin Production in Plock - OSBL scope K003 (Infrastructure for the Olefins III complex), for ORLEN S.A.

Scope

- Delivery and assembly of steel structures of pipe-racks.

- Fabrication and assembly of transmission pipelines with fastenings, steam heating as well as hot and cold insulation.

Tonnage of steel structure: 4.944,4 tons

Tonnage of pipelines with fixings: 1.328,67 tons

Insulation: 13.786 m3

Location: PLOCK, ul. Chemików 7, ORLEN S.A.

Date of realisation: 04.2024 – 12.2027

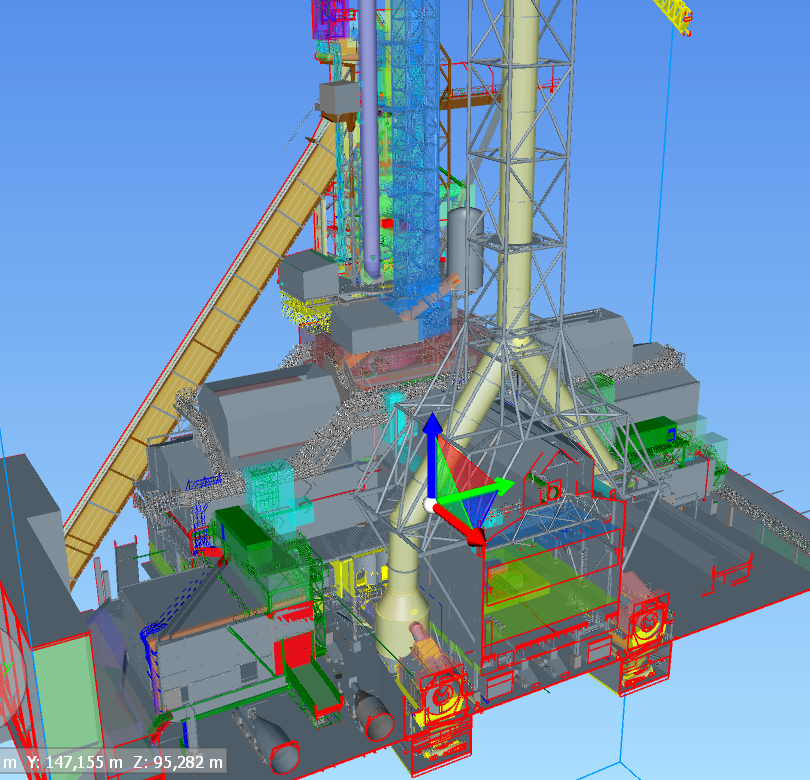

Scope:

- Delivery and assembly of steel structures for turbine building, boiler building, other buildings and technological pipe bridges.

- Assembly of HRSG boiler with pipelines according to Siemens technology.

- Assembly of gas turbine with pipelines.

- Assembly of BOP pipelines.

- Installation of a complete gas turbine set together with associated pipelines, electrical as well as control & instrumentation equipment.

Tonnage of steel structure: 4.480 tons

Tonnage of HRSG boiler: 6.220 tons

Tonnage of boiler piping: 495 tons

Tonnage of gas turbine with piping: 1.580 tons

Tonnage of BOP piping: 235 tons

Location: Rybnik, Polska

Date of realization: 09.2024 – 12.2026

Zakres prac: Opracowanie metody, składającej się 10 zadań cząstkowych, mających na celu dostosowanie jednostek wytwórczych klasy 200 MWe na bezpieczną transformację polityki energetycznej Polski.

Główne zadania:

- Zadanie 1: Zabudowa parowej nagrzewnicy powietrza do młynów na by-passie głównego kanału powietrza pierwotnego do młynów węglowych w budynku kotłowni (zdjęcie 1).

- Zadanie 2: Wykonanie częściowego by-passu ECO w postaci kanałów gorących spalin z kanału II ciągu kotła sprzed ECO w kotłowni do kanału zewnętrznego spalin za LUVO do SCR (po obydwu stronach kotła (zdjęcie 2).

- Zadanie 3: Zabudowa wymiennika ciepłowniczego (stacji ciepłowniczej) w celu utrzymania cyrkulacji w rurach opadowych z walczaka (zdjęcie 3).

- Zadanie 4: Grzanie walczaka parą technologiczną 1,7MPa (zdjęcie 4).

- Zadanie 5: Zabudowa falowników WP (2 szt.), dostawa silników 850kW i bypass 6kV (zdjęcie 5 i 6).

- Zadanie 6: Zabudowa falowników WS (2 szt.), 2 silników 1250kW i bypass 6kV (zdjęcie 7 i 8).

- Zadanie 7: Wymiana klapy szczelnej odcinającej za WS do czopucha spalin przed IOS (zdjęcie 9 i 10).

- Zadanie 8: Obniżenie ciśnienia w walczaku z 15,5 MPa do wartości wymaganej dla zapewnienia odpowiedniej cyrkulacji w układzie parownika kotła (zdjęcie 11 i 12).

- Zadanie 9: Układ recyrkulacji spalin elektrofiltra (zdjęcie 13).

- Zadanie 10: Dostawa akustycznego systemu do pomiaru rozkładu temperatury w komorze paleniskowej – AGAM (zdjęcie 14).

Termin realizacji: 10.04.2022 – 28.02.2022

Klient: ENEA Elektrownia Połaniec S.A.

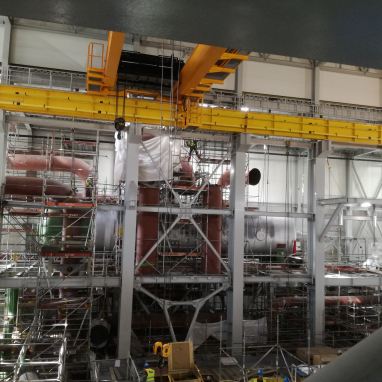

Scope of works:

- Delivery and assembly of the steel structure of the engine hall, boiler building, pumping station, flyovers and auxiliary buildings.

- Installation of two HRSG boilers with pipelines according to GE technology.

- Installation of two condensers according to GE technology.

- Installation of technological devices.

- Installation of two gas turbines.

Tonnage of steel structure: 2 x 3.650 tons.

Tonnage of HRSG boilers: 2 x 5,750 tons.

Tonnage of boiler pipelines: 2 x 340 tons.

Tonnage of condensers: 2 x 340 tons.

Tonnage of technological equipment: 2 x 100 tons.

Tonnage of gas turbines: 2 x 1.200 tons.

Location: Nowe Czarnowo near Gryfino, Poland

Date: 02.2020 – 12.2023 (ongoing)

Cogeneration unit with a capacity of min. 50 MWe and a heat source at PGE Energia Ciepła S.A.

Scope of works:

-

- Delivery and erection of steel structure for boiler building, generator hall, compressor hall, pipe bridges and other buildings.

- Installation of process equipment and flue gas ducts.

- Assembly of technological pipelines: steam, mains water, glycol, compressed air, urea and other auxiliary pipelines.

- Tonnage of steel structures: 980 tons

- Tonnage of process equipment: 520 tons

- Tonnage of flue gas ducts: 95 tons

- Tonnage of pipelines: 250 tons

Date of realisation: 2023-2025

Scope of work:

- dismantling of the heating oil tank, V = 2000 m3

- delivery and assembly of the steel structure of the boiler house and technological flyover (180 tons)

- delivery and assembly of 6 boiler units with a capacity of 31 MWt each (6x86 tons)

- delivery and assembly of a Gas Reduction and Measurement Station with a capacity of 20.000 Nm3 / h

- construction of a high pressure gas pipeline DN150

- delivery and assembly of technological devices (pumps, economizers)

- delivery and assembly of technological pipelines (190 tons)

Location: Rzeszów

Date of realization: 05/05/2022 - 02/28/2023

Scope of work: design and construction of a new heat and electricity generation source in a high-efficiency gas cogeneration system with a capacity of up to 20 MW with the necessary technical infrastructure - EC Słoneczna as part of the Słupsk Bioenergy Cluster

- Location: Słupsk, Poland

- Realisation: 2020-2022

- Final client: Engie EC Słupsk

Detailed scope of work:

- Heat and power plant building

- 2 gas engines

- Main Supply Point - GPZ

- 110kV line

- 1100 m3 heat accumulator

- Installations: gas, oil, heating, sewage, urea and SCR with the necessary infrastructure

- Water treatment station

- Flue gas exhaust system with 2 chimneys

Scope of works:

- Construction of a boiler house for 2 boilers (100 Mg / h in delivery and optionally 50 Mg / h).

- Delivery and assembly of a steel chimney.

- Construction of a two-levels electrical building BUE with a communication pylon.

- Construction of a new technological flyover connecting the boiler house with the existing flyover.

- Delivery and assembly of a gas reduction and measurement station.

- Delivery and assembly of tanks and expanders.

- Delivery and installation of the feed water tanks (ZWZ) and pumps.

Tonnages:

- Steel structure of buildings – 320 tons

- Chimney – 60 tons

- Support steel structure for boiler – 99 tons

- Boiler – 189 tons

- Feed water tanks (ZWZ) – 28,69 tons

- Technological pipelines - 143 tons

Location: Kędzierzyn Koźle

Date of realization: 2021 - 2024

Client: Zakłady Azotowe Kędzierzyn S.A. AZOTY Group

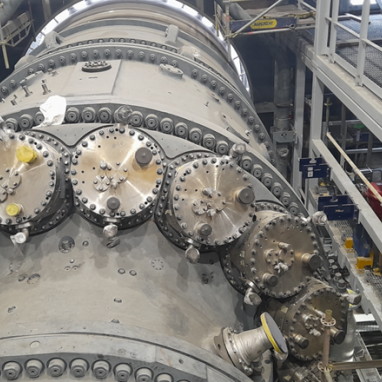

- Scope of works: Assembly of steel structure for turbine and boiler building, LuVo, SCR and other auxiliary buildings in total tonnage of 4.500 tons. Installation of process equipment: preheater LuVo, SCR, coal mill, flue gas ducts.

- LuVo: 160 tons

- SCR and channels: 300 tons

- Coal mill: 400 tons

- Location: Pulawy, Poland

- Date: 2020-2021

- Client: Grupa Azoty Puławy (Poland)

Scope of work:

• Installation of the secondary structure on the roof of the electrostatic precipitator with a demage beam.

• Installation of pumps and tanks in IOS buildings.

• Manual assembly of lifting beams under the roof of the boiler house with service platforms.

• Installation of the hydraulic system on rod gates.

• Installation of auxiliary installations for coal mills.

• Installation of the roof structure of the slag storage facility.

• Installation of the gypsum warehouse roof structure.

Scope implemented by Polimex Energetyka:

- assembly of steel structures (4,200 tons)

- assembly of technological devices (250 tons)

- assembly of light casings (10,500 m2)

- assembly of technological pipelines (800 tons)

Scope implemented by Polimex Energetyka:

- assembly of steel structures (400 tons)

- integration and assembly of ducts (400 tons)

- dismantling of ducts (150 tons)

- assembly of technological devices (52 tons)

- assembly of technological pipelines (55 tons)

Scope implemented by Polimex Energetyka:

- assembly of steel structures (450 tons)

- assembly of technological devices (520 tons)

- assembly of light casings (800 m2)

- assembly of technological pipelines (220 tons)

EPC

Supply and installation of two turbine generator sets with a capacity of 100 MWe each, along with design and accompanying work in the Żerań CHP. Client: the Power Plants in Warsaw SA (PGNiG Termika SA). Contract value: PLN 140 million Tz11 + PLN 171 million Tz12.

Implementation of Wet Flue Gas Desulphurization Installation in the Power Plant Rybnik. Client: Power Rybnik. Value of the contract: PLN 228 million.

Construction of the installation of renewable energy production based on biomass in the CHP Bialystok SA. Client: CHP Bialystok SA. Contract value: PLN 85 million.

Construction of a new Water Treatment Plant in the Nitrogen Plant in Kędzierzyn. Contract value: PLN 63 million.

Coaling plant construction in Belchatow. Client: SANDVIK Mining and Construction. Contract value: PLN 83.8 million.

Design, construction, supply of machinery and equipment, and installation of a complete Flue Gas Desulphurization block No. 10 - 500 MW. Client: "Kozienice" SA Power Plant (ENEA Production SA). Contract value: PLN 75.5 million.

Construction of a new power unit with a fluidized bed boiler, backpressure turbine, two peak boilers and heat accumulator in the Bielsko-Biala EC1 Power Plant. Client: PKE SA. Contract value: PLN 409.7 million.

Construction of a catalytic denitrification plant for OP-430 block boilers No. 10, 14, 15 and OP-380 boiler No. 11 in Siekierki. Client: Vattenafall Heat Poland SA (PGNiG Termika SA). Contract value: PLN 140 million.

Professional assembly

PLN Pressure part assembly in two boilers with a capacity of 1100 MW at Neurath. Client: Hitachi Power Europe, Alstom Power Boiler. Contract value: PLN 107.1 million.

Pressure part assembly in a boiler within the package No. 1,2,4,5 for a block of 858 MW in the Belchatow power plant. Client: ALSTOM Power Sp. z o. o. and RAFAKO SA. Boiler Factory. Contract value: PLN 59.5 million.

Foreign contracts

PLN PAPER MILL IGGESUND, SWEDEN. Scope of works: supply and installation of steel structures with walls and roof construction. Client: Andritz Oy. Net value of the contract: PLN 31 million.

WASTE TO ENERGY PLANT, HELSINGBORG, SWEDEN. Scope of works: supply and erection of steel structure and channels (c. 1800 tons), installation of a boiler (about 800 tons), delivery and installation of piping (about 150 tons), installation of process equipment. Client: Babcock & Wilcox Vølund A/S, NCC Construction Sverige AB. Value: PLN 38.8 million.

IGNIS POWER PLANT, SPREMBERG, GERMANY. Scope of works: supply and installation of steel structures. Client: Baumgarte Boiler Systems GmbH. Value: PLN 15.2 million.

PULP MILL ENCE, HUELVA, SPAIN. Scope of works: supply and installation of steel structures with walls and roof construction. Client: Andritz Oy. Value: PLN 13.9 million